There are some links in the manufacturing of goods that are more essential than others. One of these is that of sealing technologies. The New Zealand market for industrial seals has grown exponentially, and there are several innovative technologies and developments that keep driving the industry towards a greener and more efficient future, including seal innovations nz.

What do we mean by the seal industry?

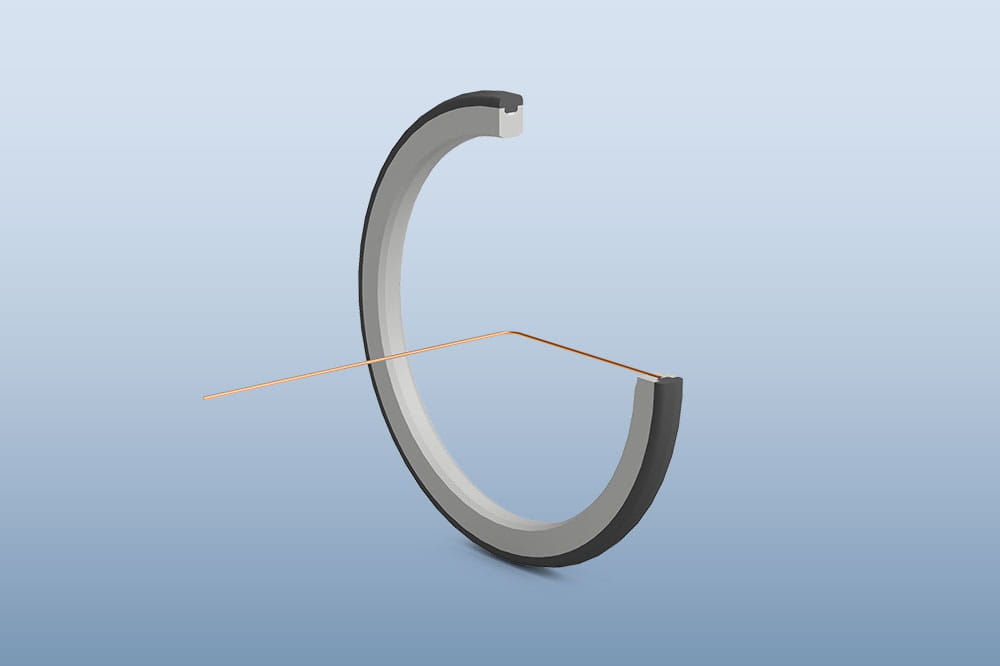

Seals can be found in machines as large as airplanes and as small as sensitive medical equipment. Their main function is to prevent leakage, retain lubrication, block contamination, and hold pressure. In other words, seals help optimize performance and increased its process reliability. They can used in both static and rotary systems.

There are a large range of seals on the market, including but not limited to: O-rings, hydraulic seals, rotary seals, pneumatic seals, mechanical seals, etc. There are also industry specific seals, as the products are used in a large range of operating areas.

The innovative technology applied in the seal industry has helped the market grow and expand their operations. With the help of industrial seals, companies have been able to create more sustainable and long-lasting machine processes, as the seals prevent wear and tear from weather, temperatures, corrosion, and more.

Since its beginning, the sealing industry has grown exponentially, and the growth does not seem to slow. In 2021 the global sealing industry was worth around 11.8 billion USD. According to market experts, the industry is set to grow another 6 billion USD by 2029, creating a compound annual growth rate (CAGR) of 5.7 per cent.

Innovative Seal Technologies

The birth of the sealing market was innovative in itself, and the pioneering mindset and research on the topic keeps going on high gears. Technological advancements are in motion every single day, and the seal imports and exports will expand further as they begin to be implemented into the industry.

3D Printing

One of the innovative techniques that have improved the industry so far is the implementation of three-dimensional printing technology. Prior to the idea of 3D printing, seals were produced by injection or compression molding, where seals were sculpted by producing lots of waste. With the help of 3D printing, seals are now only produced with the accurate amount of material for each seal, thus saving manufacturers both time and money.

Furthermore, the technology has sped up the process of creating seal prototypes, which can be key in research and development of new techniques, shapes, and sizes. By doing so, it expands the flexibility of the already agile industry.

FFKM, PTFE and Nanotechnology Materials

Other researchers have looked at how the materials used can be more sustainable. As a result, materials such as FFKM and PTFE have been developed. PTFE stands for polytetrafluoroethylene and is more commonly known as Teflon. The material has shown resistance to temperature, corrosion, and electricity, making it a good and durable sealant.

FFKM produces similar characteristics to the PTFE but has shown potential for more extreme situations. For example, they have been adopted in aerospace manufacturing where temperatures can fall as low as 200 degrees Celsius.

Some have also discussed the potential use of nanotechnology and their self-healing properties in the sealing industry. These features, though they still haven’t gained ground, might help make seals even more versatile and flexible.

NZ Branch Leader: Seal Innovations (SIL)

One of the largest innovators within this field is the Australia-New Zealand joint company Seal Innovations (SIL). The company has combined several branches within the sealing industry in order to become a premium supplier of high-quality sealing equipment to its customers. The company imports seal and gasket supplies from both local and global manufacturers in order to continue their long running history of seal innovations nz.

The SIL team stands on three branch pillars: Seal Imports, NAK, and Alliance Seal, the latter of which formed after combining Sealcom, Interseal, and Specialised Gaskets. In combining these three power houses, SIL has been able to build up a breadth of operations and seal and gasket product range unlike most companies in the branch.

Conclusion

The sealing industry maintains an innovative mindset in producing durable business tech solutions. Both global and local seal manufacturers are working hard towards adopting new innovative technologies in order to create even better wear-and-tear protection.